Our Production Details

INDICATOR OF OUR POTENTIAL

Press Roof Prefabricated Section

The outer layer panels are cut according to standard panel dimensions (125 cm in width, and 250 cm, 280 cm, or 300 cm in height). Polystyrene foam is also cut and prepared in the same dimensions. The cut polystyrene foam is placed between the two outer layer panels. Under the press, high pressure is applied, firmly bonding the panels and the polystyrene foam. This process ensures the integrity and durability of the panel. This insulation material provides heat, sound, and water insulation to the panels.

Insulation Material: Polystyrene foam (EPS) is provided with a density of 16 kg/m³. Durable materials like cement-based particle boards or gypsum boards are typically used. Pressed panels are mass-produced in factories and can be quickly and easily assembled on-site. This allows prefabricated structures to be built quickly and efficiently. The outer layer panels are paintable and offer an aesthetic finish with decorative coatings.

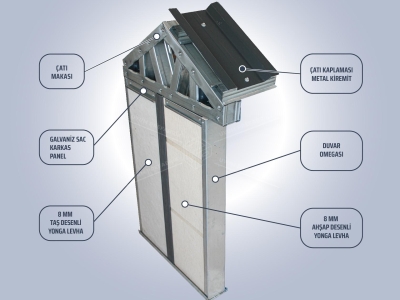

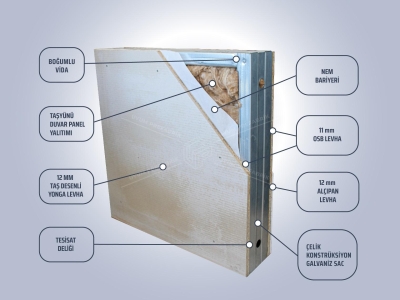

Light Steel Structure Exterior Wall Section

Light steel structure systems primarily use galvanized steel coils as the raw material for the components. This is a building technology that employs galvanized steel profiles. The profiles used in this system are produced through the cold-forming method. Galvanized steel is transformed into profiles of the desired cross-section using roll-forming machines. C and U-shaped profiles are the most commonly used types.

Steel coils are fed into roll-forming machines, where they are transformed into the desired profile shapes. The machine passes the sheet through several stages to produce structural components such as steel columns, beams, and trusses. The shaped profiles are cut to specific lengths, and mounting holes are made.

The wall panels, truss panels, ceiling panels, roof panels, and supporting columns are assembled using a bolting system. After assembly, the structure is closed with cladding materials to create a smooth wall surface. The exterior surfaces of the load-bearing wall panels made from galvanized steel profiles are covered on-site.

This system offers flexible design possibilities and architectural aesthetics. It provides a lighter, faster-to-build, and cost-effective alternative compared to reinforced concrete buildings. The light steel structure system excels in durability, energy efficiency, flexibility, and aesthetics.

Light Steel Structure System

The light steel structure system is created using steel profiles produced in roll-forming machines. Galvanized steel coils are coated to resist rust. These steel coils are fed into roll-forming machines, which unroll and flatten them. The flattened steel sheets are then cold-formed into the desired profile shapes (such as C, U, etc.) using the cold-forming method. These machines pass the steel through several stages to create the desired profile sections.

Cutting and drilling: The shaped profiles are cut to specific lengths according to project requirements. Necessary connection holes are drilled for screwing and bolting processes. The produced profiles are numbered and marked to ease assembly during construction. The size accuracy of the profiles, hole placements, and overall structural integrity are carefully checked.

Profiles that pass quality control are carefully packed and prepared for transport to the construction site. At the construction site, the profiles are assembled in the specified order according to the project. Bolted connections are used for assembly, ensuring that the building components are joined quickly and securely. This process offers fast and cost-effective construction solutions.

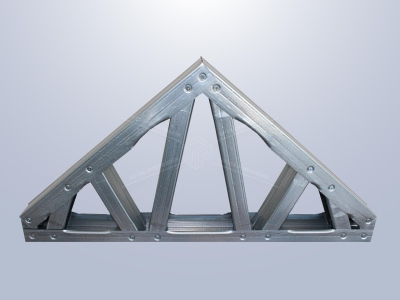

Roof Truss

The roof truss used in the assembly of prefabricated buildings is a critical component that ensures both the strength and aesthetics of the building's roof. Roof trusses are made from galvanized (corrosion-resistant) steel. The galvanized coating enhances the steel's resistance to rust. The trusses are shaped in special roll-forming machines in the roll-form line. These machines transform the steel into specific profile sections, forming the internal profile of the roof truss.

The joints are made using bolts and screws without welding. Special galvanized sheet eaves are installed on both sides of the building. Ventilation holes are created at the truss ridges (V-shaped areas) to prevent condensation. Metal gutters are used to control the flow of water from the roof.

The profile dimensions of the roof truss's external profile vary according to the project of the prefabricated building. This allows for the production of trusses in different sizes based on the design and requirements of the structure. Roof trusses are numbered and coded during the production phase and are transported to the site according to the project specifications. They are then assembled using bolted connections.

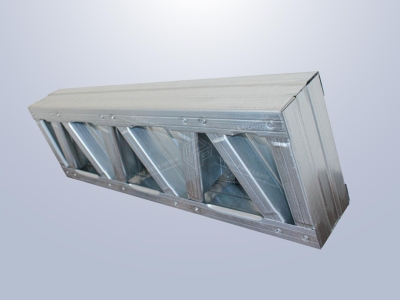

Intermediate Frame

The intermediate profiles used in the construction of prefabricated buildings are critical components that connect two floors and support the second floor above the first. These profiles are made of galvanized (corrosion-resistant) steel and are shaped using a special roll-forming line.

Intermediate profiles in prefabricated structures are a crucial part of the building's load-bearing system, ensuring the secure and durable installation of the second floor on top of the first. These profiles safely bear the weight of the second floor and contribute to the overall stability of the structure. This design enables the quick, cost-effective, and safe construction of prefabricated buildings.

The profiles are specially shaped in roll-form machines and are made of galvanized steel for added durability. The intermediate steel construction consists of specially bent profiles, ensuring robust support and stability for the overall structure.